Plastic Fabrication

Source Solutions offers a wide range of custom solutions to meet all of your plastic fabrication needs. We are experts in Rotational Molding with years of experience and offer complete Turnkey Service with all fabrication work from concept, through design and fabrication, to a finished product.

Our Mission:

- Provide high quality, cost effective plastic products to our customers.

- Create customized, integrated product solutions that add value, combined with personal service that differentiates us from competitors.

Source Solutions welcomes the opportunity to present you its diverse range of in-house capabilities for all your plastic fabrication needs.

Big or small, let us quote your upcoming project.

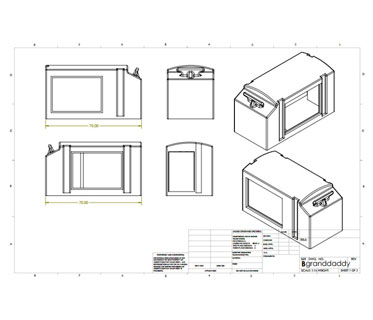

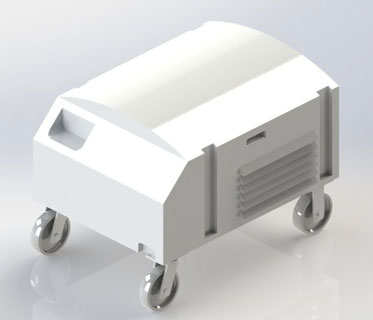

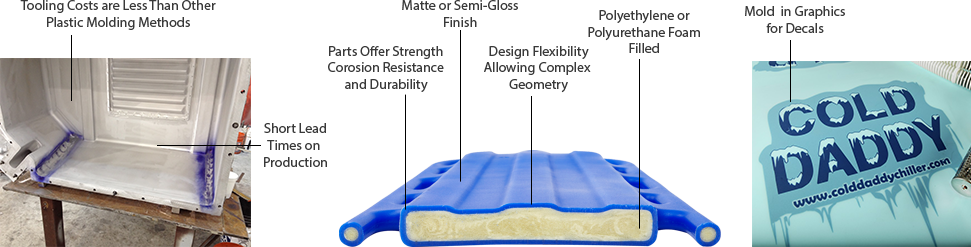

Turn-Key Project: For IRSA ---- Cold Daddy Chiller

Source Solutions recently worked with the team from IRSA (International Recovery Systems of America) on a complete turnkey project from concept, through design and fabrication, to a finished product. The pictures below show the project start to finish and is a good example of our diverse range of in-house capabilities to produce all your plastic and metal fabrication needs.

Click the pictures to enlarge

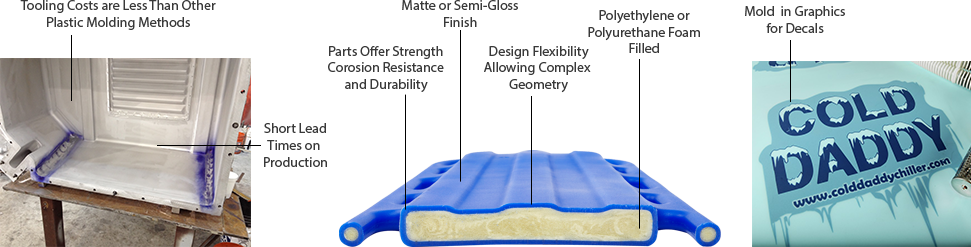

Rotational Molding

We specialize in Rotational Molding and offer complete turnkey service Concept to finished product, we are your one-stop rotational molding partner.

Rotational Molding, also called rotomolding or rotocast, is a thermoplastic process for producing hollow parts by placing powder resin into a hollow mold and then rotating that mold biaxially in an oven until the resin melts and coats the inside of the mold. The mold is then cooled and the part is removed from the mold. Rotational molding can produce small to large, simple to complex parts.

Advantages of Rotational Molding:

Source Solutions welcomes the opportunity to present you its diverse range of in-house capabilities for all your plastic and metal fabrication needs.

Let us quote your upcoming project!